-

-

-

About the company

-

For dealer

-

Customer support

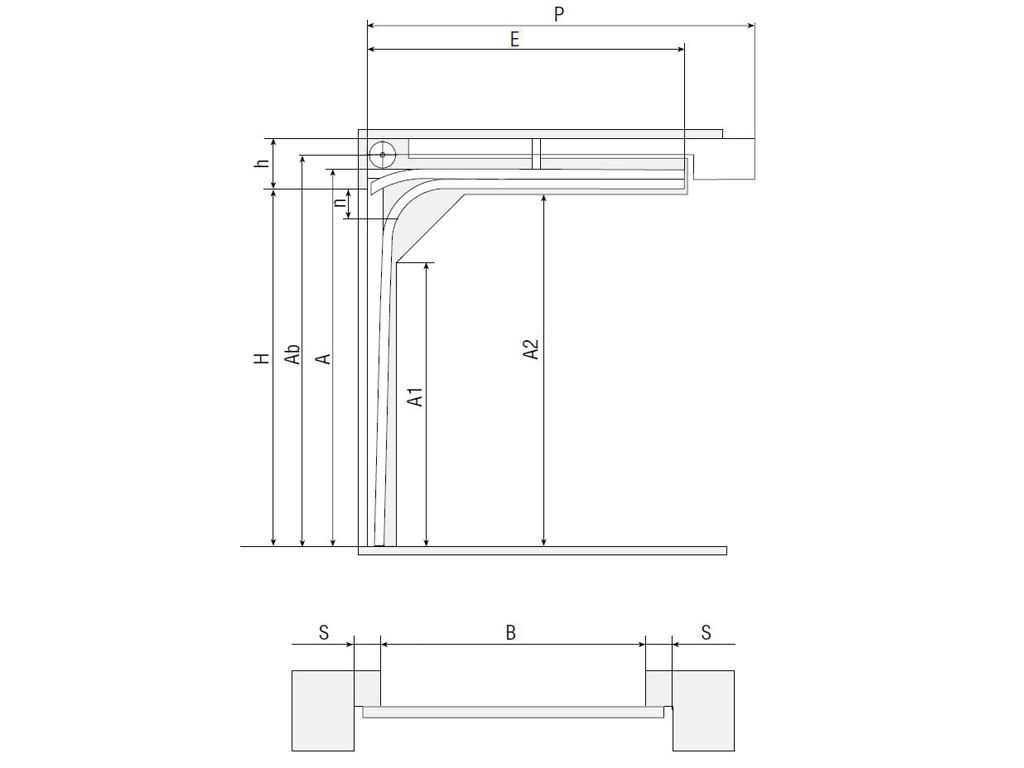

Low rise, drum at the front.

| Symbol, parameter name | Calculation formula |

|---|---|

| H, mm Opening height | H |

| h, mm Headroom height | h ≥ 160 |

| B, mm Opening width | B |

| A, mm Angle track height | H + 54 |

| Ab, mm Height of shaft axle and drum | A + 59 |

| A1, mm Vertical track height | А - 543 |

| A2, mm Horizontal track height | А - 106 |

| E, mm Horizontal track length | Н + 315 |

| S, mm Minimum side room clearance | 120 |

| P, mm Door opener position | Н + 1 185 |

| n, mm Clear opening | 190 (without drive); 0...10 (with ceiling drive) |

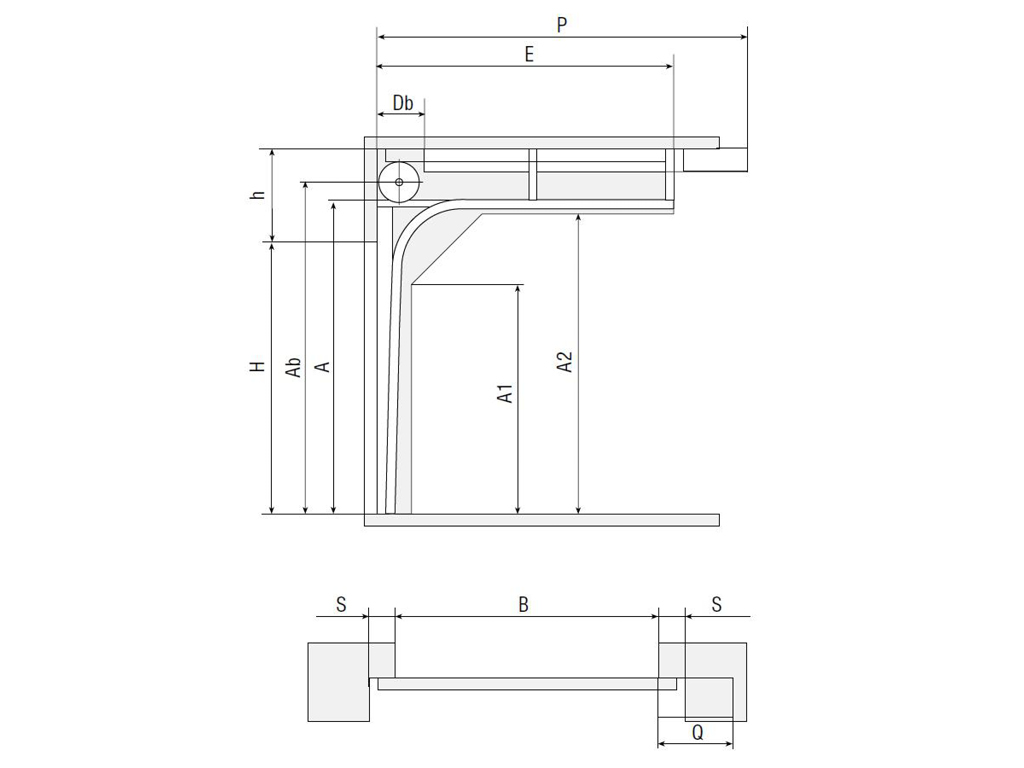

Standard lift.

| Symbol, parameter name | Calculation formula |

|---|---|

| H, mm Opening height | H |

| h, mm Headroom height | R381: ≥ 420; R305: ≥ 350 |

| B, mm Opening width | B |

| A, mm Angle track height | R381: H+235; R305:H+165 |

| Ab, mm Height of shaft axle and drum | A + 97 |

| A1, mm Vertical track height | R381: A - 580; R305: A - 490 |

| A2, mm Horizontal track height | А - 110 |

| E, mm Horizontal track length | R381: H+200; R305:H+250 |

| Db, mm Torsion spring operation space | 100 |

| S, mm Minimum side room clearance | 120 |

| P, mm Door opener position | Н + 1 060 |

| Parameter | Value | Notes |

|---|---|---|

| Number of cycles | 25 000 | |

| Force of manual opening and closing, N | 150 | |

| Door leaf weight, kg/m² | 8,5 |

1. Sections of the door leaf must move smoothly along the guides, and the door itself must be balanced, i.e., its weight must be compensated by the torque of the springs.

2. Manual opening and closing of the gate is carried out only with the help of a handle.

3. When opening and closing the gate manually, do not apply much force to it. Sudden jerks are unacceptable.

4. Make sure that people and animals are not in the area of the gate while it is operating.

5. It is strictly prohibited to move under the moving door leaf, as this can lead to injury.

6. Do not subject the gate to impacts or interfere with its free movement when opening and closing.

7. Do not expose the guides and rollers to contamination, as this can lead to disruption of smooth operation, and in the case of an electric drive, this can lead to its overload and failure.

8. Make sure that there are no foreign objects or debris in the opening while the blade is moving. Their presence can lead to skewing and jamming of the gate.

| Packing in cardboard | Packaging features |

|---|---|

| Description | The guide system and panel of sectional doors have a rigid combined packaging made of cardboard and polystyrene foam, covered with stretch film; the complete set is packed in a corrugated cardboard box and sealed with packaging film; All packages are equipped with information stickers containing order data, as well as the company logo |

| Contents | Five-layer cardboard, polystyrene foam, stretch film, tape |

| Width, mm | 500–800 |

| Height, mm | 200–400 |

| Length, mm | 2 100–3 600 |

| Gross weight, kg | Up to 100 |

| Number of items in the packaging | Shield packaging — from 4 to 5 panels; package of guides — 1 guide system; packaging of components — box with complete set |

| Packing in cardboard box | Packaging features |

|---|---|

| Length, mm | 550 |

It is recommended to store sandwich panels in their original packaging in a horizontal position on a flat surface for no more than 6 months from the date of production in closed warehouses or under a canopy. The panels must be protected from direct sunlight, precipitation and contamination.

Low rise, drum at the front.

| Symbol, parameter name | Calculation formula |

|---|---|

| H, mm Opening height | H |

| h, mm Headroom height | h ≥ 160 |

| B, mm Opening width | B |

| A, mm Angle track height | H + 54 |

| Ab, mm Height of shaft axle and drum | A + 59 |

| A1, mm Vertical track height | А - 543 |

| A2, mm Horizontal track height | А - 106 |

| E, mm Horizontal track length | Н + 315 |

| S, mm Minimum side room clearance | 120 |

| P, mm Door opener position | Н + 1 185 |

| n, mm Clear opening | 190 (without drive); 0...10 (with ceiling drive) |

Standard lift.

| Symbol, parameter name | Calculation formula |

|---|---|

| H, mm Opening height | H |

| h, mm Headroom height | R381: ≥ 420; R305: ≥ 350 |

| B, mm Opening width | B |

| A, mm Angle track height | R381: H+235; R305:H+165 |

| Ab, mm Height of shaft axle and drum | A + 97 |

| A1, mm Vertical track height | R381: A - 580; R305: A - 490 |

| A2, mm Horizontal track height | А - 110 |

| E, mm Horizontal track length | R381: H+200; R305:H+250 |

| Db, mm Torsion spring operation space | 100 |

| S, mm Minimum side room clearance | 120 |

| P, mm Door opener position | Н + 1 060 |

| Parameter | Value | Notes |

|---|---|---|

| Number of cycles | 25 000 | |

| Force of manual opening and closing, N | 150 | |

| Door leaf weight, kg/m² | 8,5 |

1. Sections of the door leaf must move smoothly along the guides, and the door itself must be balanced, i.e., its weight must be compensated by the torque of the springs.

2. Manual opening and closing of the gate is carried out only with the help of a handle.

3. When opening and closing the gate manually, do not apply much force to it. Sudden jerks are unacceptable.

4. Make sure that people and animals are not in the area of the gate while it is operating.

5. It is strictly prohibited to move under the moving door leaf, as this can lead to injury.

6. Do not subject the gate to impacts or interfere with its free movement when opening and closing.

7. Do not expose the guides and rollers to contamination, as this can lead to disruption of smooth operation, and in the case of an electric drive, this can lead to its overload and failure.

8. Make sure that there are no foreign objects or debris in the opening while the blade is moving. Their presence can lead to skewing and jamming of the gate.

| Packing in cardboard | Packaging features |

|---|---|

| Description | The guide system and panel of sectional doors have a rigid combined packaging made of cardboard and polystyrene foam, covered with stretch film; the complete set is packed in a corrugated cardboard box and sealed with packaging film; All packages are equipped with information stickers containing order data, as well as the company logo |

| Contents | Five-layer cardboard, polystyrene foam, stretch film, tape |

| Width, mm | 500–800 |

| Height, mm | 200–400 |

| Length, mm | 2 100–3 600 |

| Gross weight, kg | Up to 100 |

| Number of items in the packaging | Shield packaging — from 4 to 5 panels; package of guides — 1 guide system; packaging of components — box with complete set |

| Packing in cardboard box | Packaging features |

|---|---|

| Length, mm | 550 |

It is recommended to store sandwich panels in their original packaging in a horizontal position on a flat surface for no more than 6 months from the date of production in closed warehouses or under a canopy. The panels must be protected from direct sunlight, precipitation and contamination.