-

-

-

About the company

-

For dealer

-

Customer support

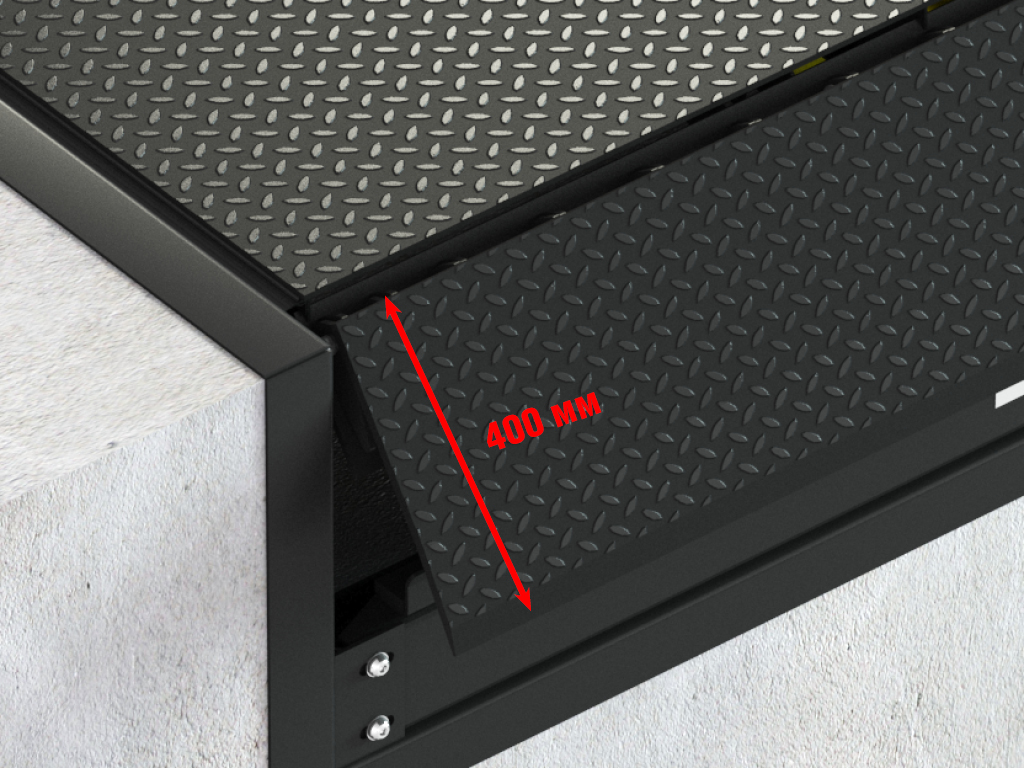

Standard lip 400 mm. 35 mm bevel. Whole rectangular lip for trucks with one-size load bed.

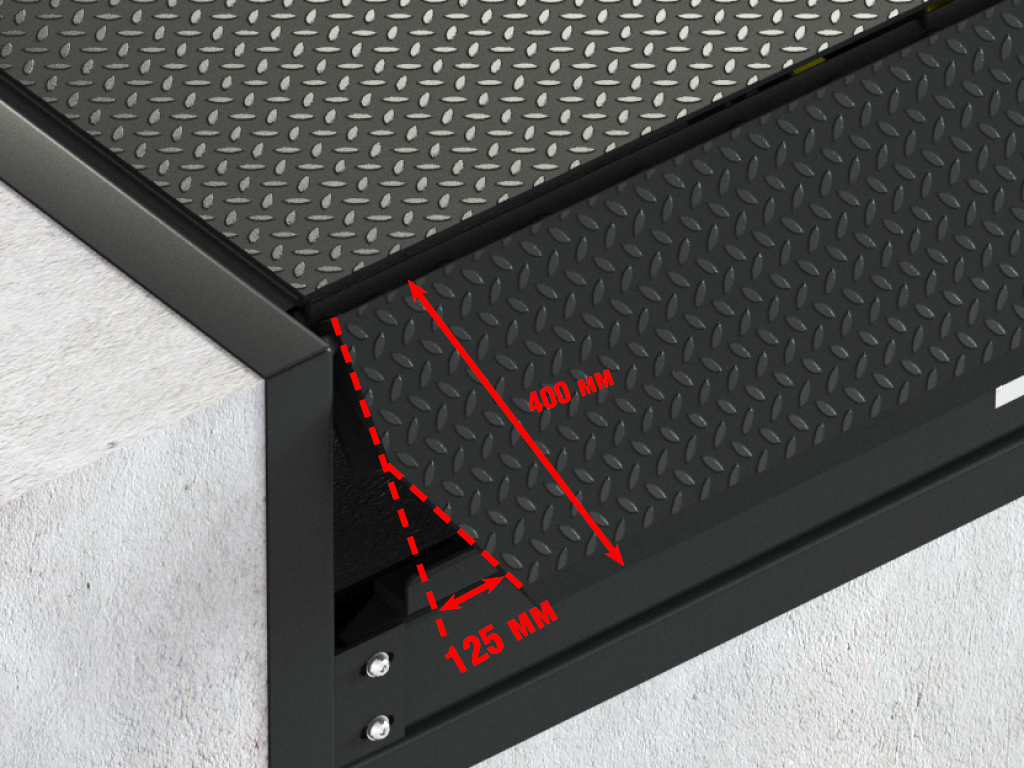

Wedge-shaped lip. 35 mm bevel. Whole, without segments. Such levelers are ideal for trucks with different-size load beds or in case a truck parks not in the center of the loading dock preventing truck damage.

Lip without bend. 35 mm bevel. Whole, without segments. Rectangular lip ideal for trucks with one-size load bed and loaders with low or very low clearance.

| Parameter | Value | Notes |

|---|---|---|

| Length, mm | 2 500 | |

| Width, mm | 1 800; 2 000 | |

| Weight, kg | 850 | |

| Load capacity, kg (kN) | 6 000 (60) | |

| Maximum point load, Н/mm² | 1,3 | 6 mm top sheet |

| Preparation of steel surface before application of paints, class | Sa 2 | |

| Thickness of paint layer, not less than, mkm | 60 | |

| Operating temperature range, °С | from -30 to +50 |

Conduct routine inspections and maintenance of the dock leveler to ensure its safe and smooth operation.

Keep people and goods clear of working area while operating the dock leveler.

Keep overhead door fully open while operating the dock leveler.

Make sure the vehicle is properly parked against the dock bumpers. Chock the wheels if needed.

Do not drive on the leveler unless the lip is securely positioned on the truck bed and has a minimum of 100 mm overlap on its surface.

Ensure that the control unit location allows the operator to clearly see and control dock leveler operation.

Use dock levelers with 1,3 Н/mm² point load only with standard forklifts having inflatable wheels.

Lifting equipment: forklift truck (minimum load capacity — 35 kN, fork length — not less than 2 000 mm); crane (minimum load capacity — 20 kN).

Mounting equipment: welding machine (5–200 A); 3 mm welding electrodes.

Mechanical Dock Leveler

Certificate of Conformity (loading equipment)

Certificate of Conformity #151299198

Certificate of Conformity #151299199

Certificate of Conformity #151299200

Technical Data for Mechanical Dock Leveler

MODLE embeded mechanical dock leveler

MODLIE embeded mechanical dock leveler

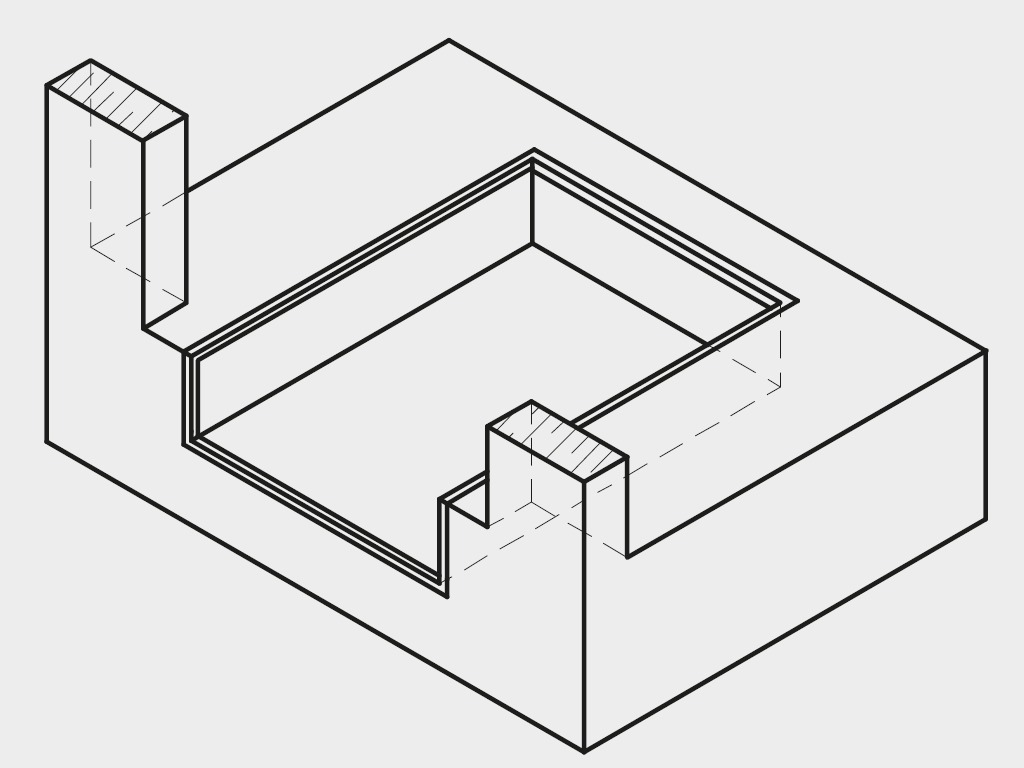

MODLE pit preparation drawing (without hydraulic lift)

MODLE pit preparation drawing (with hydraulic lift)

MODLS pit preparation drawing

Scheme of force distribution in dock leveler pits

Installation drawings for BR250x250x100, BR450x250x100, BRC510x250x330, BRM610x250x175, BRM600x364x110 dock bumpers

Installation drawings for BRSP(16)465x250x165, BRSP(16)465x250x165S, BRSP(10)460x250x160, BS500x255x205, BS800x255x205 dock bumpers

DoorHan warrants the dock leveler with hinged lip to operate properly for a period of 2 years from purchase date for retail and dealer orders.

Standard lip 400 mm. 35 mm bevel. Whole rectangular lip for trucks with one-size load bed.

Wedge-shaped lip. 35 mm bevel. Whole, without segments. Such levelers are ideal for trucks with different-size load beds or in case a truck parks not in the center of the loading dock preventing truck damage.

Lip without bend. 35 mm bevel. Whole, without segments. Rectangular lip ideal for trucks with one-size load bed and loaders with low or very low clearance.

| Parameter | Value | Notes |

|---|---|---|

| Length, mm | 2 500 | |

| Width, mm | 1 800; 2 000 | |

| Weight, kg | 850 | |

| Load capacity, kg (kN) | 6 000 (60) | |

| Maximum point load, Н/mm² | 1,3 | 6 mm top sheet |

| Preparation of steel surface before application of paints, class | Sa 2 | |

| Thickness of paint layer, not less than, mkm | 60 | |

| Operating temperature range, °С | from -30 to +50 |

Conduct routine inspections and maintenance of the dock leveler to ensure its safe and smooth operation.

Keep people and goods clear of working area while operating the dock leveler.

Keep overhead door fully open while operating the dock leveler.

Make sure the vehicle is properly parked against the dock bumpers. Chock the wheels if needed.

Do not drive on the leveler unless the lip is securely positioned on the truck bed and has a minimum of 100 mm overlap on its surface.

Ensure that the control unit location allows the operator to clearly see and control dock leveler operation.

Use dock levelers with 1,3 Н/mm² point load only with standard forklifts having inflatable wheels.

Lifting equipment: forklift truck (minimum load capacity — 35 kN, fork length — not less than 2 000 mm); crane (minimum load capacity — 20 kN).

Mounting equipment: welding machine (5–200 A); 3 mm welding electrodes.

DoorHan warrants the dock leveler with hinged lip to operate properly for a period of 2 years from purchase date for retail and dealer orders.

Mechanical Dock Leveler

MODLE embeded mechanical dock leveler

MODLIE embeded mechanical dock leveler

MODLE pit preparation drawing (without hydraulic lift)

MODLE pit preparation drawing (with hydraulic lift)

MODLS pit preparation drawing

Scheme of force distribution in dock leveler pits

Installation drawings for BR250x250x100, BR450x250x100, BRC510x250x330, BRM610x250x175, BRM600x364x110 dock bumpers

Installation drawings for BRSP(16)465x250x165, BRSP(16)465x250x165S, BRSP(10)460x250x160, BS500x255x205, BS800x255x205 dock bumpers